- Need Any Help: +1 647-760-5505 or

- [email protected]

The spring brake sub-system is a crucial component of the air brake system used in commercial vehicles. It serves two primary functions:

In emergency situations, such as a sudden loss of air pressure in the brake system, the spring brakes are designed to activate automatically. This helps bring the vehicle to a stop safely and quickly, preventing accidents or collisions.

When the vehicle is parked, the spring brakes can be manually activated to ensure that the vehicle remains stationary. This is essential for parking on inclines or uneven surfaces, as it prevents the vehicle from rolling.

Understanding how the spring brake sub-system works is critical for ensuring the safety of both the vehicle occupants and other road users. Proper operation of the spring brakes can prevent accidents and injuries.

Commercial vehicles are required to meet safety standards and regulations. Knowledge of the spring brake system and its maintenance requirements is necessary to comply with these regulations and ensure the vehicle’s roadworthiness.

A well-maintained spring brake system contributes to the overall efficiency and performance of the vehicle. It allows for smooth operation and reliable braking, enhancing the driver’s control over the vehicle.

Regular maintenance and understanding of the spring brake system can help prevent costly repairs or replacements. Timely identification and resolution of issues can save both time and money for vehicle owners and operators.

Proper maintenance practices, such as inspecting and lubricating components, can extend the lifespan of the spring brake system. This ensures that the system continues to function effectively over the vehicle’s lifespan.

In summary, the spring brake sub-system plays a vital role in the safety, compliance, efficiency, cost-effectiveness, and durability of commercial vehicles. Understanding its functions and maintenance requirements is essential for safe and reliable operation.

Spring brakes are designed to work when you are parking your vehicle or in an emergency when your service brakes fail. This chapter explains the operation and function of the spring brake subsystem.

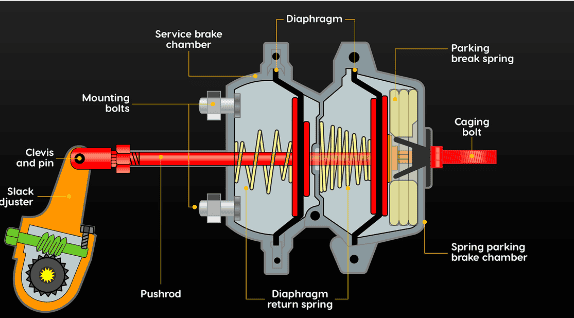

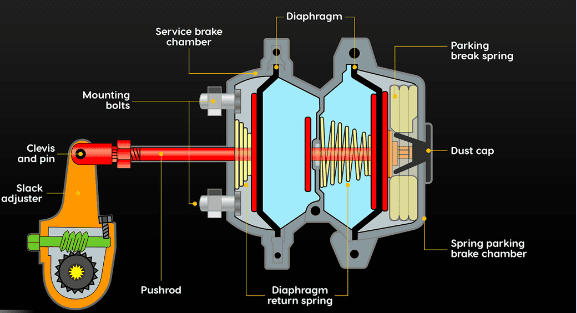

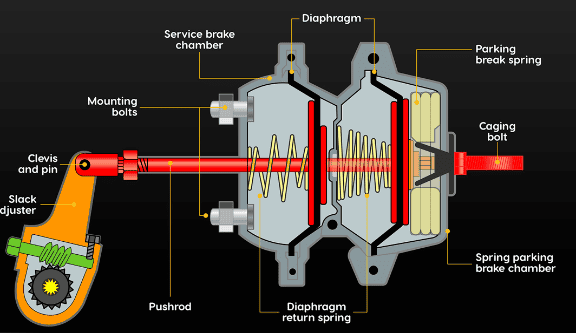

All vehicles with air brakes must have a way of stopping if the service brake system fails. Most vehicle manufacturers combine this emergency braking system with a parking brake system using spring brakes. Spring brakes are not air-applied like service brakes. They apply when air pressure leaves the brake chamber and release when air pressure builds up in the chamber. Spring brakes use a different type of brake chamber from service brakes. A brake chamber that includes both service brake and spring brake sections is called a spring brake chamber. Spring brake chambers apply the brakes by means of a large coil spring that provides enough force to hold the brakes in the applied position, instead of using air to apply the brakes.

A distinctive feature of spring brake systems is the use of specialized brake chambers known as spring brake chambers. These chambers encompass both the service brake and spring brake sections, with the spring brake section using a large coil spring to apply the brakes. This design differs significantly from traditional service brake chambers and is easily recognizable due to its added size and visible spring brake section.

The spring brake section is “piggy-backed” onto the service brake section within the chamber. These two sections function independently, with the service brake section operating similarly to a standalone service brake chamber. To release the spring brakes, sufficient air pressure (usually between 70-80 psi or 483-552 kPa) must be supplied to compress or “cage” the large coil spring. If the air pressure falls below this level, the spring brakes engage automatically.

While some vehicles can still be driven with the spring brakes applied, they do not provide the same braking power as a full-service brake application. It’s crucial to ensure that the air brake system maintains adequate air pressure (70-80 psi or 483-552 kPa) to prevent the spring brakes from activating unintentionally.

Due to the high tension of the large coil spring used in spring brake chambers, tampering, damage, or corrosion can lead to the spring releasing suddenly. This can result in hazardous situations with violent motion of parts in the brake chamber. Therefore, it is strongly advised never to attempt servicing or repairing any air brake chamber without proper training and equipment.

Understanding the intricate operation and safety considerations of spring brakes and spring brake chambers is paramount for maintaining a safe and reliable air brake system in commercial vehicles. Regular inspections, adherence to pressure requirements, and caution during maintenance are essential practices to ensure optimal brake performance and driver safety.

The manual caging method is a technique used by technicians to manually compress or “cage” the spring in a spring brake chamber. This process is essential in certain emergency situations or when a spring brake chamber fails and needs temporary disabling.

A spring brake control valve plays a pivotal role in the operation of spring brakes in commercial vehicles, serving both parking and emergency braking functions. Typically, these valves are push/pull type valves with a distinct yellow, four-sided knob located conveniently near the driver for easy access and operation. The majority of spring brake control valves follow a standard operation sequence: pushing the valve supplies air and releases the spring brakes, while pulling the valve exhausts air and applies the spring brakes. However, some vehicles may have this function reversed, although the valve’s functions are typically clearly described on or near the control valve for driver reference. In certain cases, vehicles may utilize a toggle-type valve for spring brake control.

It’s crucial for drivers to be familiar with the type of control valve used in their vehicle to ensure proper operation and response in different scenarios. Additionally, some trucks and tractors may feature a separate control called a tractor parking-brake control valve. This specialized valve is designed to release the spring brakes on the tractor while keeping the trailer spring brakes applied. It is often identified by a round blue knob for easy recognition.

Spring brake control valves are engineered to respond swiftly to air brake system pressure dropping below a specific level, typically around 60 psi (414 kPa). When this occurs, the valve exhausts the remaining air that holds the spring brakes in the released position, leading to an automatic and sudden application of the spring brakes, resulting in an uncontrolled vehicle stop. Drivers can easily identify this situation as the control valve knob will pop out when the spring brakes engage due to low air pressure.

Understanding the importance of maintaining normal air brake system pressure, which typically operates between 70-80 psi (483-552 kPa), is critical. If air pressure drops below this range, the spring brakes will automatically begin to apply, emphasizing the significance of maintaining proper air pressure levels for safe vehicle operation.

In emergency situations where the service brakes fail, drivers can rely on the spring brake control valve to apply the spring brakes effectively. However, the effectiveness of a vehicle’s spring brakes heavily depends on the condition and proper adjustment of the brakes themselves. If brakes are improperly adjusted or out of adjustment, the spring brakes may not effectively stop or hold a vehicle stationary. It’s essential to remember that poor brake adjustment not only reduces the ability of service brakes to stop a vehicle but also diminishes the effectiveness of spring brakes in stopping or holding a vehicle in place. Regular inspection, maintenance, and adjustment of brakes are crucial for ensuring optimal brake performance and vehicle safety.

An anti-compounding valve is an essential component in air brake systems, designed to prevent a dangerous condition known as brake “compounding.” This condition occurs when the service brakes and spring brakes are both applied simultaneously, leading to a buildup of pressure between the two brake systems. The anti-compounding valve acts as a safety mechanism to prevent this scenario and ensure the proper functioning of the brake system.

Anti-compounding valves are typically installed in the air brake system between the service brake chambers and the spring brake chambers. Their strategic placement ensures that they can effectively monitor and regulate pressure differences between the two brake systems.

The presence of anti-compounding valves is essential for ensuring compliance with safety regulations and standards in commercial vehicles. These valves play a critical role in maintaining the integrity and reliability of the brake system, reducing the risk of brake failures due to compounding.

Many buses and motor coaches utilize a different type of parking and emergency brake system known as the DD3 Safety Actuator, which does not rely on a large spring in the brake chamber like traditional spring brake chambers. Instead, a DD3 brake chamber features a unique design with three air line connections, distinguishing it from the standard two-line configuration of spring brake chambers.

Internally, DD3 chambers are equipped with a mechanical mechanism that allows the brakes to be locked in the applied position when needed. This mechanism provides an additional layer of safety and control over the braking system.

Operationally, a control valve similar to the one used in conventional spring brake systems is used to apply the emergency and parking brakes in DD3 chambers. Releasing the spring brakes in a DD3 chamber requires a specific procedure: first, the control valve must be operated to release the brakes, followed by pressing the brake pedal for a duration of three to five seconds. This sequence ensures the proper release of the brakes and allows for safe and controlled braking operations.

The DD3 Safety Actuator offers a reliable and efficient alternative to traditional spring brake chambers, providing enhanced control and functionality for parking and emergency braking in buses and motor coaches. Its unique design and operation make it a valuable component in ensuring the safety and performance of these vehicles on the road.