1. Impact of Vehicle Weight on Braking

Increased Demand on Brakes:

- As the weight of your vehicle increases, the demand for the brake system also increases.

- In an air brake system, this means greater brake application pressure is needed. You must press the brake pedal farther to achieve this increased pressure.

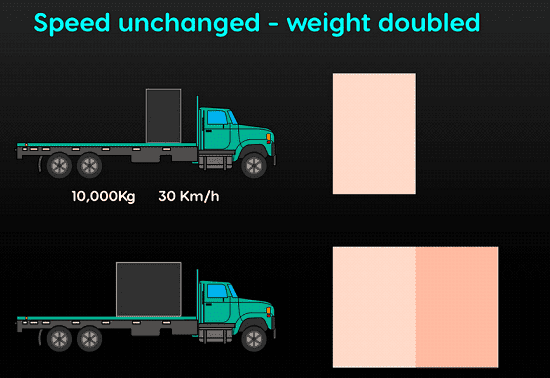

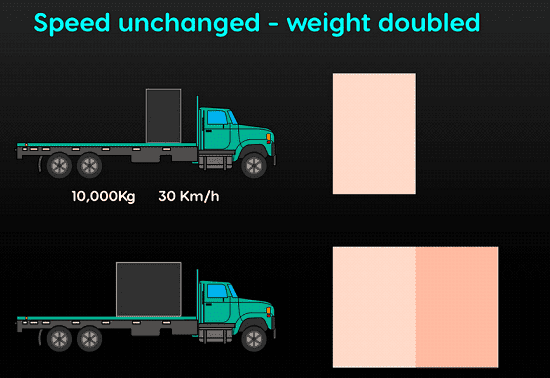

Doubling Vehicle Weight:

- Doubling the weight of your vehicle results in doubling the stopping distance. For example, if a truck carrying 10,000 kilograms requires 30 meters to stop, the same truck carrying 20,000 kilograms will require 60 meters to stop.

Effects of Increased Weight:

- Higher Brake Temperatures: Heavier vehicles generate more heat in the brake components during braking, which can lead to brake fade.

- Greater Wear and Tear: The additional weight causes more wear and tear on brake components, requiring more frequent maintenance.

- Potential Brake Failure: Overloading the vehicle can exceed the brake system’s capacity, potentially leading to brake failure, especially in emergency situations.

2. Impact of Vehicle Speed on Braking

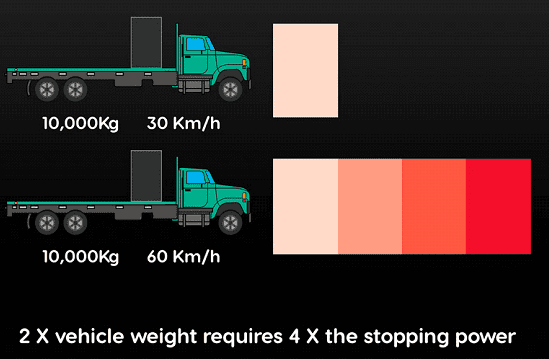

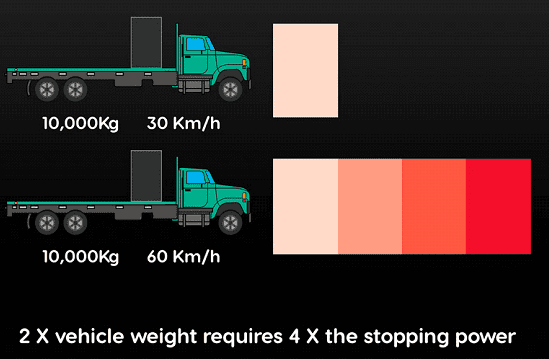

Exponential Increase in Stopping Distance:

- As vehicle speed increases, the stopping distance increases at a rate greater than the increase in speed.

- For example, if you double the speed of the vehicle, the stopping distance increases by four times. If a vehicle traveling at 50 km/h requires 30 meters to stop, the same vehicle traveling at 100 km/h will require 120 meters to stop.

Greater Braking Force Required:

- Higher speeds require greater braking force to slow down or stop the vehicle. This increased force results in higher brake application pressure and more work for the braking system.

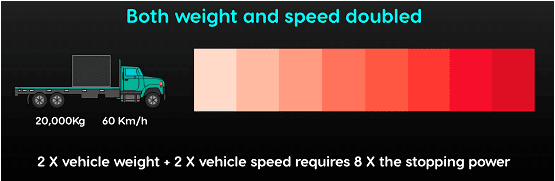

3. Combined Effects of Weight and Speed

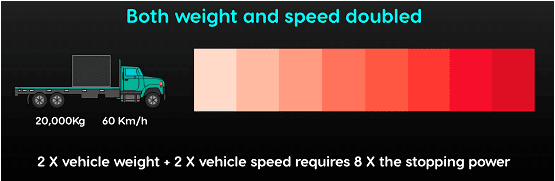

Multiplicative Effect on Stopping Distance:

- the speed, the stopping distance increases by eight times. For example, if a truck at its original weight traveling at 50 km/h needs 30 meters to stop, doubling the weight and speed will require 240 meters to stop.

Practical Implications for Drivers:

- Maintaining Safe Following Distances: Drivers should maintain greater following distances when carrying heavier loads or traveling at higher speeds to account for the increased stopping distance.

- Proper Load Management: Avoid exceeding the vehicle’s rated capacity to prevent overloading the brake system. This ensures the brakes can function effectively and safely.

- Regular Brake Maintenance: Regularly check and maintain the brake system to ensure it is in good condition and capable of handling the demands placed on it by varying weights and speeds.

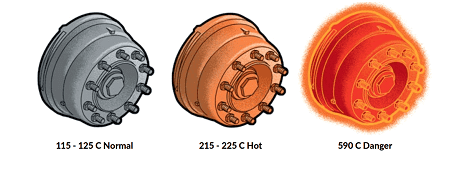

4. Brakes Create Heat

Brakes are an essential component of any vehicle, providing the necessary force to slow down or stop. One critical aspect of brake operation that drivers must understand is how brakes convert the energy of a moving vehicle into heat. This process and its implications are vital for maintaining brake performance and ensuring vehicle safety.

The Conversion of Energy

When a vehicle is in motion, it possesses kinetic energy, which is the energy of motion. Brakes function by converting this kinetic energy into thermal energy (heat). This conversion process involves friction, where brake pads or shoes press against brake rotors or drums to create the necessary friction force. This friction generates heat as it dissipates the kinetic energy of the vehicle.

Frequency and Type of Brake Use

The amount of heat generated by the brakes depends on the frequency and type of brake use:

- Repeated Braking: When brakes are used repeatedly, such as during prolonged descents down long or steep hills, significant heat is generated due to continuous friction.

- Stop-and-Go Traffic: In urban environments with frequent stopping and starting, brakes are often engaged and disengaged, leading to repeated heat buildup.

- Severe Braking: During emergency stops or when heavy braking is required to avoid collisions, a substantial amount of heat is produced in a short period.

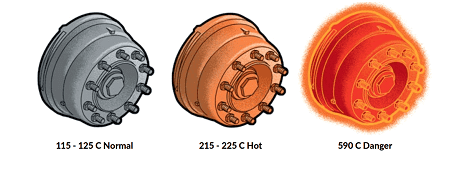

Impact of Heat on Brake Performance

As the brakes generate heat, their operating temperature increases. Under normal conditions, brakes are designed to handle a certain amount of heat. However, excessive heat can lead to higher-than-normal operating temperatures, which can have several effects on brake performance:

5. Brake Fade

As brake components heat up, their effectiveness can be significantly reduced. This phenomenon, known as brake fade, occurs when the brakes lose their ability to generate sufficient friction due to high temperatures. Brake fade is particularly concerning because it requires the driver to press harder on the brake pedal to achieve the desired braking force. The severity of brake fade can vary depending on the vehicle and driving conditions.

Causes of Brake Fade

Heat Buildup in Brake Components:

- During continuous or severe braking, such as driving down a long hill or in stop-and-go traffic, the friction between the brake pads and rotors (or brake shoes and drums) generates a substantial amount of heat.

- In commercial vehicles with air brake systems, compressed air is used to apply the brakes. The heat generated during braking can affect the performance of the brake components, particularly the friction materials (pads or shoes) and the brake drums or rotors.

Vehicle-Specific Factors:

- Brake fade is more noticeable in some vehicles than others due to differences in brake system design, the materials used, and the vehicle’s load capacity.

- Vehicles with smaller or less efficient braking systems are more prone to brake fade under heavy use.

Extreme Cases of Brake Fade

In extreme cases, such as traveling down a long hill at excessive speed or with an overloaded vehicle, brake fade can become so severe that it results in a significant loss of brake force. This situation can be extremely dangerous, as the driver may be unable to slow down or stop the vehicle effectively. Severe brake fade can occur due to:

- Excessive Speed: Traveling at high speeds increases the kinetic energy that the brakes must dissipate, generating more heat.

- Overloading: Carrying a load that exceeds the vehicle’s rated capacity places additional stress on the braking system, leading to faster heat buildup and more severe brake fade.

Impact of Driving Habits on Brake Heat

Driving habits play a crucial role in managing brake heat and preventing brake fade. Good driving habits can help reduce the amount of heat generated in the brakes and maintain their effectiveness:

- Anticipating Road Conditions: By anticipating traffic flow, signals, and potential obstacles, drivers can apply brakes more smoothly and avoid sudden, harsh braking.

- Maintaining Safe Following Distance: Keeping a safe distance behind other vehicles allows for gradual braking and reduces the need for frequent, hard brake applications.

- Moderate Speeds: Driving at moderate speeds, especially on descents, helps keep brake temperatures within safe limits.

Auxiliary Braking Systems

Some vehicles are equipped with auxiliary braking systems that help manage brake heat and prevent brake fade. These systems include:

- Engine Brakes: These use engine compression to slow down the vehicle, reducing the reliance on the primary brake system.

- Retarders: These are fitted onto the driveline and use hydraulic or electric means to slow the vehicle.

- Auxiliary Brakes: These additional braking mechanisms assist in controlling vehicle speed and preventing excessive brake temperatures.

Benefits of Auxiliary Braking Systems

- Reduced Brake Heat: Auxiliary braking systems help dissipate kinetic energy without relying solely on the primary brakes, thus reducing heat buildup.

- Extended Brake Life: By reducing the workload on the primary brake system, auxiliary brakes help extend the life of brake components.

- Improved Safety: These systems enhance overall vehicle control and safety, especially in situations where prolonged braking is required, such as on long descents.

Practical Tips for Drivers

To effectively manage brake heat and prevent brake fade, drivers should adopt the following practices:

- Use Engine Brakes on Descents: When driving downhill, use engine brakes or shift to a lower gear to help control speed and reduce reliance on the primary brakes.

- Avoid Overloading: Ensure that the vehicle is loaded within its rated capacity to prevent excessive demands on the brake system.

- Regular Maintenance: Regularly inspect and maintain the brake system, including checking for wear on brake pads or shoes and ensuring that air compressors and other components are functioning correctly.

-

- Safe Driving Practices: Maintain a safe following distance, anticipate road conditions, and drive at moderate speeds to minimize the risk of brake fade.

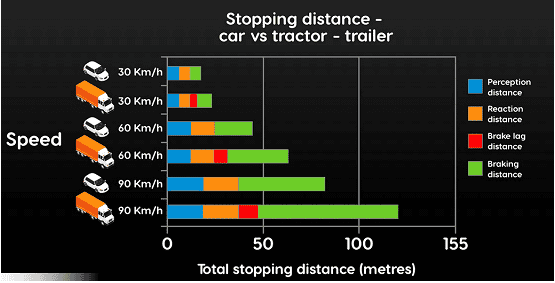

6. Vehicle Stopping Distance for Commercial Vehicles

Understanding vehicle stopping distance is crucial for the safe operation of commercial vehicles. Stopping distance is the total distance a vehicle travels from the moment a driver perceives a need to stop until the vehicle comes to a complete stop.

Split-Second Delay in Air Brake Systems

Commercial vehicles equipped with air brake systems experience a split-second delay, typically up to half a second, between when the brake pedal is pressed and when the brakes are fully applied. This delay is due to the time required for air to travel through the brake lines and engage the brake mechanisms. This delay must be taken into account when calculating stopping distances and maintaining safe following distances.

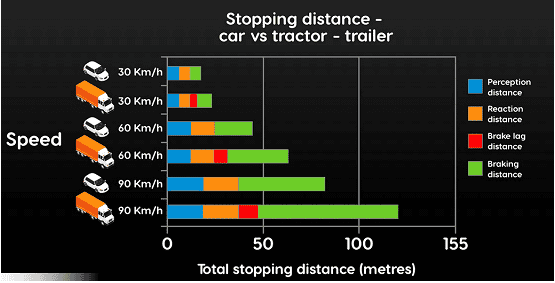

The image shown compares the total stopping distance of a car and a tractor-trailer at different speeds (30 km/h, 60 km/h, and 90 km/h). The stopping distance is broken down into several components, each represented by different colored bars. The graph illustrates how the total stopping distance increases with speed for both types of vehicles.

Components of Stopping Distance

Perception Distance (Blue):

- The distance a vehicle travels while the driver perceives a need to stop.

- It remains constant across all speeds for both the car and the tractor-trailer.

Reaction Distance (Orange):

- The distance a vehicle travels while the driver reacts and begins to apply the brakes.

- This distance increases with speed for both the car and the tractor-trailer.

Brake Lag Distance (Pink):

- Specific to the tractor-trailer, this distance accounts for the time it takes for the air brake system to engage after the brake pedal is pressed

- This component is absent from the car.

Braking Distance (Green):

- The distance a vehicle travels from the moment the brakes are applied until it comes to a complete stop.

- This distance increases significantly with speed for both the car and the tractor-trailer.

Total Stopping Distance

The total stopping distance is the sum of all these components:

At 30 km/h:

- Car: The total stopping distance is relatively short, with a significant portion attributed to perception and reaction distances.

- Tractor-Trailer: The stopping distance is longer than that of the car, with an additional brake lag distance.

At 60 km/h:

- Car: The stopping distance increases, primarily due to the longer braking distance.

- Tractor-Trailer: The stopping distance increases significantly, with noticeable contributions from brake lag and extended braking distance.

At 90 km/h:

- Car: The stopping distance is much longer, with the braking distance being the largest component.

- Tractor-Trailer: The stopping distance is the longest among all scenarios, with substantial contributions from brake lag and a very extended braking distance.

7. Proper Brake Adjustment

For safe vehicle operation, especially in commercial vehicles, it is crucial to maintain the full capacity of the brake system. Proper brake adjustment ensures that the braking force is available when needed, particularly under demanding conditions. This detailed explanation covers the significance of correct brake adjustment, the consequences of improper adjustment, and the regulatory requirements for brake inspections.

Full Brake Capacity

- Normal Driving Conditions: In everyday driving, the full capacity of the brake system is not often utilized. Most braking situations involve moderate braking force.

- Safety Requirement: Despite this, the brake system must always be capable of delivering its full capacity to handle emergencies and demanding driving conditions.

Effect of Pushrod Stroke on Braking Force

- Brake Chamber Pushrod Stroke: The brake force produced at a wheel is significantly affected by the stroke of its brake chamber pushrod. The pushrod is a component that transfers force from the brake chamber to the brake mechanism.

- Excessive Stroke: When the stroke becomes excessive, it means the pushrod travels too far before the brakes are fully applied. This excessive travel reduces the efficiency and effectiveness of the brakes.

- Loss of Braking Ability: Even a small loss of braking ability may go unnoticed during normal driving. However, in situations that demand higher braking performance, such as carrying heavier loads, driving at higher speeds, navigating long downhill grades, or making emergency stops, this reduced braking capability can become critical.

Consequences of Improper Adjustment

- Severe Reduction in Braking Ability: When the brake chamber pushrod stroke exceeds the adjustment limit, the braking ability can be so diminished that the vehicle may not stop or hold properly.

- Emergency Situations: In emergencies, this can lead to dangerous situations where the vehicle cannot stop in time, increasing the risk of accidents.

Importance of Proper Adjustment

- Maintaining Braking Force: Proper brake adjustment ensures that each brake chamber’s pushrod stroke remains within its adjustment limit, allowing the brake chamber to produce the necessary force.

- Full Braking Ability: Vehicles maintain their full braking ability only when all brakes are properly adjusted.

Regulatory Requirements

- Daily Checks: According to the Highway Traffic Act and associated regulations, vehicles equipped with air brakes must be checked at least once each day to ensure they are correctly adjusted.

- Adjustment Limits: Specific adjustment limits are prescribed for each style, size, and type of air brake chamber. These limits must be adhered to during inspections.

- Reliable Inspection Methods: Detecting brakes that are out of adjustment requires reliable inspection methods, as improper adjustment cannot be identified without thorough checks.

Practical Implications for Drivers

- Routine Inspections: Drivers and maintenance personnel must perform regular inspections to ensure all brakes are within their adjustment limits. This includes measuring the pushrod stroke and adjusting as necessary.

- Understanding Limits: Familiarize yourself with the prescribed adjustment limits for your vehicle’s brake chambers. This information is typically detailed in the vehicle’s maintenance manual or regulatory documentation.

- Proactive Maintenance: Address any signs of excessive pushrod stroke immediately to prevent loss of braking ability.

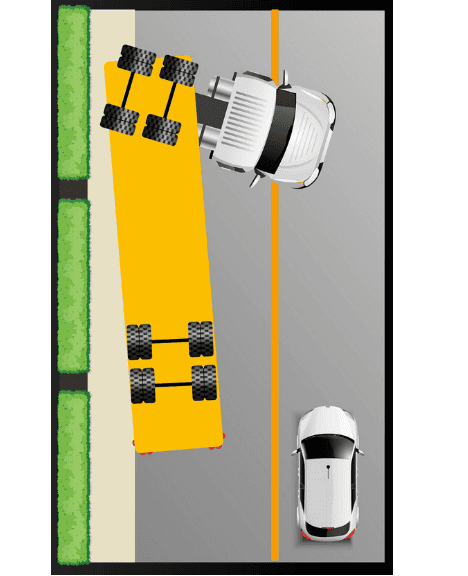

8. Antilock Braking Systems (ABS)

Anti-lock braking systems (ABS) are critical safety features in modern vehicles, designed to prevent wheel lock and maintain steering control during braking. Understanding how ABS works and its benefits can help drivers utilize this technology effectively to enhance vehicle safety and prevent dangerous situations such as jackknifing.

The Problem of Wheel Lock and Tire Skid

When a wheel locks up and a tire skids, the vehicle loses steering control and directional stability. This can occur under various driving conditions, such as:

- Emergency Braking: When a driver applies the brakes suddenly and with great force.

- Poor Traction: On slippery surfaces such as wet, icy, or gravel-covered roads.

In these situations, it can be challenging to apply the brake force needed without causing one or more wheels to lock, leading to a skid and loss of control.

How ABS Works?

Anti-lock braking systems are designed to address the issue of wheel lock. Here’s how they operate:

- Sensing Wheel Speed: ABS uses sensors to monitor the speed of each wheel on the vehicle. These sensors continuously send data to the ABS control unit.

- Detecting Abnormal Drops in Speed: If the system detects an abnormal drop in wheel speed, which indicates that a wheel is about to lock up, it responds by adjusting the brake force applied to that wheel.

- Modulating Brake Force: The ABS control unit modulates the brake force to the affected wheel, reducing it momentarily to prevent lockup and then reapplying it as necessary. This rapid modulation happens many times per second.

- Preventing Skid: By preventing the wheel from locking, ABS ensures that the tire maintains contact with the road, thereby preserving steering control and directional stability.

Benefits of ABS

The primary benefits of anti-lock braking systems include:

- Improved Steering Control: ABS prevents wheel lock and allows the driver to maintain steering control during heavy braking or on slippery surfaces.

- Enhanced Directional Stability: By preventing tire skids, ABS helps maintain the vehicle’s directional stability, reducing the risk of skidding out of control.

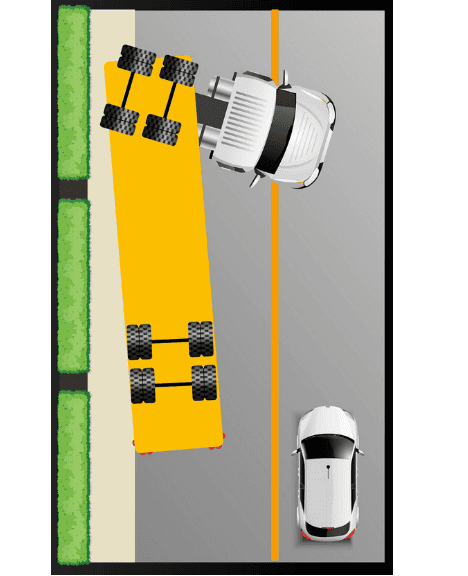

- Prevention of Jackknifing: In articulated vehicles like tractor-trailers, ABS is particularly important in preventing jackknife situations. A jackknife occurs when the trailer pushes the towing vehicle from behind until it spins around and faces backwards, forming a V or L shape. ABS reduces the likelihood of the wheels locking up and skidding, thereby maintaining alignment and control between the tractor and the trailer.

- Increased Safety: ABS significantly enhances vehicle safety by improving the driver’s ability to steer and control the vehicle during emergency braking situations.

ABS and Stopping Distance

It is important to note that while ABS improves steering control and stability, it does not necessarily shorten the stopping distance of a vehicle. Under normal driving conditions on clean, dry roads, there is typically no noticeable difference in stopping distance between vehicles equipped with ABS and those without it. The primary advantage of ABS is in maintaining control rather than reducing stopping distance.

ABS Warning and Malfunction Indicators

Vehicles with anti-lock braking systems are equipped with warning indicator lights or malfunction lamps to provide information about the status of the ABS. These indicators are crucial for driver awareness and safety:

- Dashboard Indicators: In most vehicles, ABS warning lights are mounted on the dashboard or driver console. These lights illuminate when the system is active or if there is a malfunction.

- Trailer Indicators: On trailers, ABS indicators are usually mounted in locations visible in the driver’s rear-view mirror, allowing the driver to monitor the status without turning around.

- Familiarity with Indicators: Drivers should be familiar with the location and operation of ABS indicators on their vehicles. Knowing how to interpret these indicators can help drivers respond appropriately to any issues.

Responding to ABS Malfunctions

If an ABS malfunction occurs, it is essential to understand that the regular brake function is still available. The ABS warning light will alert the driver to the malfunction, but the vehicle can still be stopped using conventional braking methods. However, the enhanced control and stability provided by ABS will not be available, so extra caution is necessary, particularly in conditions where ABS would typically provide a safety advantage.